Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

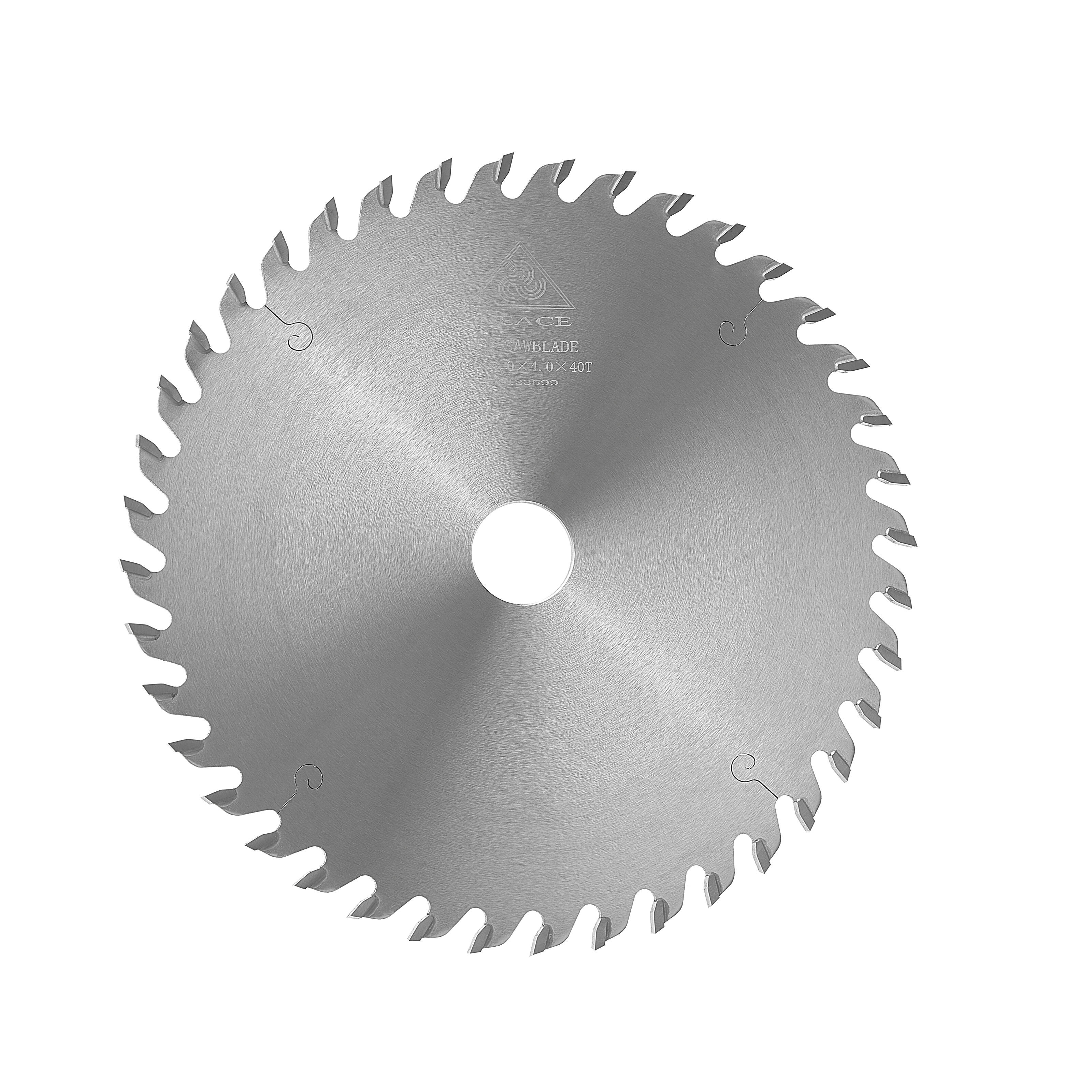

Woodworking slotted saw blade :Outside diameter170MM-200MM

It solves the three major pain points of traditional saw blade grooving and easy deflection, groove bottom burrs, and scorching materials, and realizes efficient grooving "as narrow as hair, deep as chiseling" Rigid and soft" matrix design 2.2mm thickened chrome vanadium steel matrix: 40% increase in torsional strength and eliminate slotting deflection Laser cutting pressure relief groove: release high-speed cutting stress and reduce resonance deformation

-

170*3.0*30*36T

-

170*3.5*30*36T

-

170*4.0*30*36T

-

170*4.5*30*36T

-

170*5.0*30*36T

-

170*5.5*30*36T

-

170*6.0*30*36T

-

170*7.0*30*36T

-

170*7.5*30*36T

-

170*8.0*30*36T

-

170*8.5*30*36T

-

170*9.0*30*36T

-

170*9.5*30*36T

-

170*10*30*36T

-

180*3.0*30*36T

-

180*3.5*30*36T

-

180*4.0*30*36T

-

180*4.5*30*36T

-

180*5.0*30*36T

-

180*5.5*30*36T

-

180*6.0*30*36T

-

180*6.5*30*36T

-

180*7.0*30*36T

-

180*7.5*30*36T

-

180*8.0*30*36T

-

180*8.5*30*36T

-

180*9.0*30*36T

-

180*9.5*30*36T

-

180*10*30*36T

-

200*2.0*30*40T

-

200*2.5*30*40T

-

200*3.0*30*40T

-

200*3.5*30*40T

-

200*4.0*30*40T

-

200*4.5*30*40T

-

200*5.0*30*40T

-

200*5.5*30*40T

-

200*6.0*30*40T

-

200*6.5*30*40T

-

200*7.0*30*40T

-

200*7.5*30*40T

-

200*8.0*30*40T

-

200*8.5*30*40T

-

200*9.0*30*40T

-

200*9.5*30*40T

-

200*10*30*40T

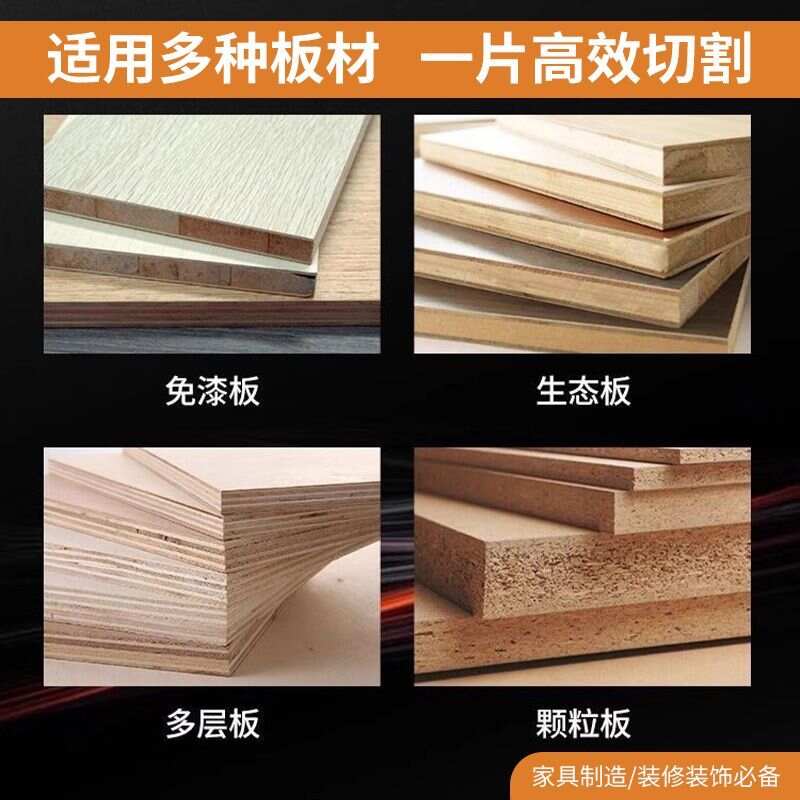

A woodworking grooving saw blade is a cutting tool used to create grooves of specific widths and depths in wood, often used in processes such as drawer slides and board splicing. Here's a snapshot of its offerings: • Material: Common are carbide and PCD diamond. Carbide is cost-effective and suitable for ordinary solid wood cutting; PCD diamond has high hardness and is more suitable for cutting precious wood or veneer wood-based panels, which can reduce wear and avoid chipping. • Features: It has the characteristics of low noise, no wobbling, high precision, and long life of the saw blade. Some high-quality saw blades are sharp and can achieve burr-free cutting, which can improve the processing quality of woodworking products.

• Type: It can be divided into single blade blade and multi-blade combined saw blade. The single blade is suitable for the situation where the groove width is fixed; The multi-blade combination saw blade can be adjusted to open grooves of different widths by adjusting the blade spacing, which is highly flexible. • Tooth shape: Commonly used tooth shapes include flat teeth, helical teeth, trapezoidal teeth, etc. Flat teeth can make the bottom of the groove flat, suitable for grooving process; The trapezoidal teeth are suitable for sawing veneers, fireproof panels, etc., and can obtain high sawing quality; The helical saw edge is of good quality and is suitable for sawing all kinds of wood-based panels.

• Specifications: The blade diameter range is wide, small table saws are usually suitable for saw blades with a diameter of 100-200mm, and large push table saws can be selected with saw blades with a diameter of 250-400mm. Users need to choose the appropriate diameter according to the grooving depth, and pay attention to the saw blade hole diameter matching the size of the equipment spindle. • Applicable machine tools: It can be used for woodworking grooving saws, milling machine tools, woodworking trenching machines and other woodworking equipment, different equipment has different requirements for the specifications and installation methods of saw blades, so it is necessary to reasonably choose the adapted saw blade